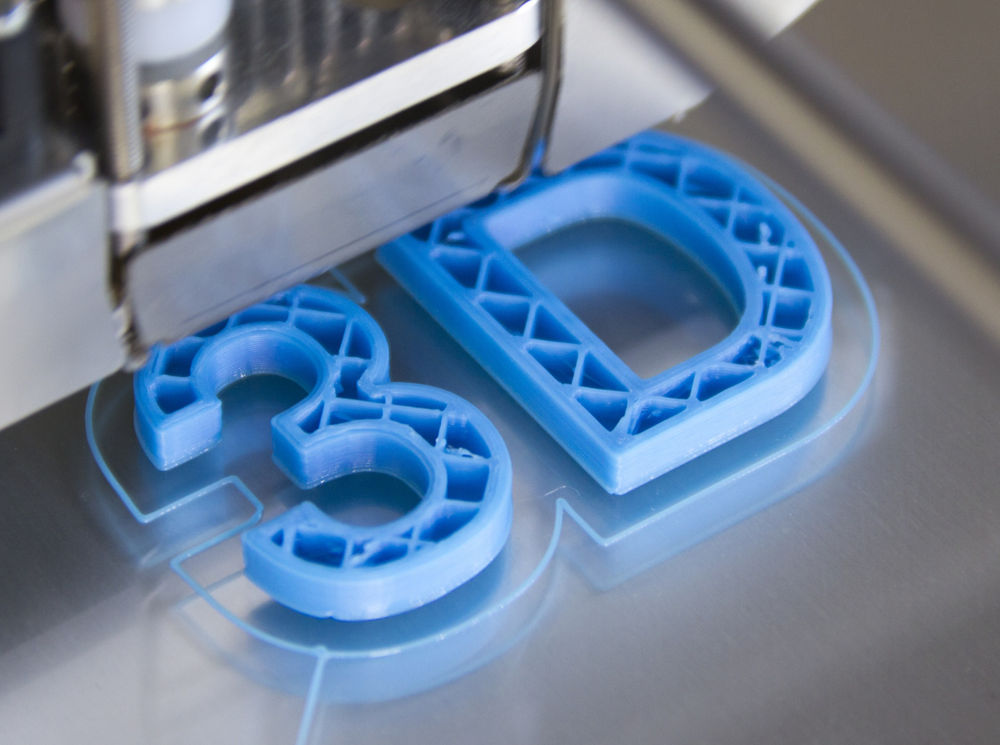

Why 3D Printing?

For a technology that has been in existence since the early 1980’s, 3D Printing is a manufacturing process that, until recently, hasn’t made a ton of progress in its efficiency of operation. The past decade has brought an immensity of strides for “Additive Manufacturing,” and has opened up possibilities to a multitude of materials as well. Anything from rubber soled shoes, to car body panels, to medical grade heart valves…AM is completely revolutionizing the manufacturability of parts in any and all industries.

The technology first came about with Charles Hull’s invention of stereolithography (SLA), later patented by Huck’s company 3D Systems; where they worked with a variety of polymer (plastic) materials. As computers evolved with Additive, there was an influx of universities/research institutions that began to dabble with AM in attempts to refine the technology. In the early 2010’s we saw massive 3D Printing PR campaign, with much of the hype focused on the end consumer. Printer manufacturers painted a picture of there being a printer in the household of every American, but this was not the case.

A pivot in marketing was all it took to get the technology back on track with a newfound focus in the industrial applications that these printers could tackle. Today the space is massively competitive with a wide range of established and startup companies developing their own secret sauce to constantly improve how parts can be printed. Anything from small desktop printers for the hobbyist/tinkerer…all the way up to sophisticated metal printers that exceed a million-dollar price tag. 3D Printing knows no boundaries and is beginning to find its place in makerspaces, high schools, classrooms, military bases, design studios, and an array of other destinations. Whether it be medical, automotive, aerospace, design, automotive, manufacturing, or any industry…3D Printing is #making an impact.

Below are just a few examples of how 3D Printing is revolutionizing the way parts are made:

Rapid Prototyping – This method is by far the most widely adopted form of Additive Manufacturing in shops across the nation. 3D Printing saves its users tens of thousands of dollars in the traditional tooling/setup costs by way of CNC machining, casting, or molding prototype parts. With printers as cheap as a couple hundred dollars, 3D Printing allows designers of all skill levels to have a part in a matter of hours to test for form, fit, and function. In most cases, if you can design a part into a CAD model…you can 3D Print parts!

Tooling/Fixturing – When running jobs on CNC mills, a popular methodology for holding a part is done by way of a vise. But what happens when the part you are holding isn't perfectly square? Printing soft jaws, or other workholding fixtures is just another way that production machine shops can incorporate Additive into their workflow. Other applications include 3D printed circuit boards, printing injection molding patterns, & more!

High Volume Production – The maturation of the product life cycle is when the technology has evolved far enough to be adapted into other use cases. Companies like 3DEO are now able to utilize repeatable Additive Manufacturing processes to be able to mass produce metal components that can be cost competitive with traditional methods suchas CNC machining, injection molding, and casting.

One Assembly Pieces – One cost manufacturers have to take into account when producing most parts is not only the production expenses, but also the cost to have these various pieces inspected and assembled. Often times you would have machined parts that would need to be welded together in order to achieve a finished, end-result part. With 3D Printing, engineers are now able to include a multitude of features and different materials onto a part that is printed in one fully assembled unit. Not only does this cut down in install time, but it can often use less material, and even produce a denser, more durable part.

Complex Geometries – A drawback from traditional manufacturing methods is that they are limited to the shape and complexity that can be achieved on machines like CNC and injection molding. While there still are a few limitations with 3D Printing, it allows the designer to incorporate features that were once impossible to produce otherwise. Features like variable wall thicknesses, and complex internal valves are just a few of the things that 3D Printing can tackle that no other machine on the market can.

End Use Parts – Product designers and manufacturers are now able to produce their final product via 3D Printing. Now printers are capable of printing maintenance items on different equipment, print aerospace components that go into space, and even print pieces that can

be sold and installed/consumed right off the printer bed. From custom keychains to entire dashboards/car parts….3D printing is changing the way we produce everyday items.

Whether it is a mass production part, or simply a plastic fidget spinner…3D Printing has proven itself to be an emerging market with infinite applications. The positive implications associated with 3D Printing are seemingly endless, with a new invention or discovery coming out every day. With its limited design restrictions, many industries are slowly being introduced to Additive in the design/prototype phase for developing new products. There are medical device companies 3D printing prosthetics, and others companies like Invisalign are 3D Printing custom fit solutions for the dental industry, and some medical companies even printing prosthetic limbs! Though these machines are not perfect, they serve as a starting point for further innovation for seemingly every industry imaginable.

If you can’t tell by now, I am a complete and avid 3D Printing enthusiast, and fully believe it will revolutionize not only the industrial world….but soon enough it will change the consumer world as well. I invite you to share with my any 3D Printing projects you have done in the past, any questions, comments, tips, or anything else related to 3DP!